Vantaa Energy invests in expanding waste management services – Boost Brothers setting up a project alliance

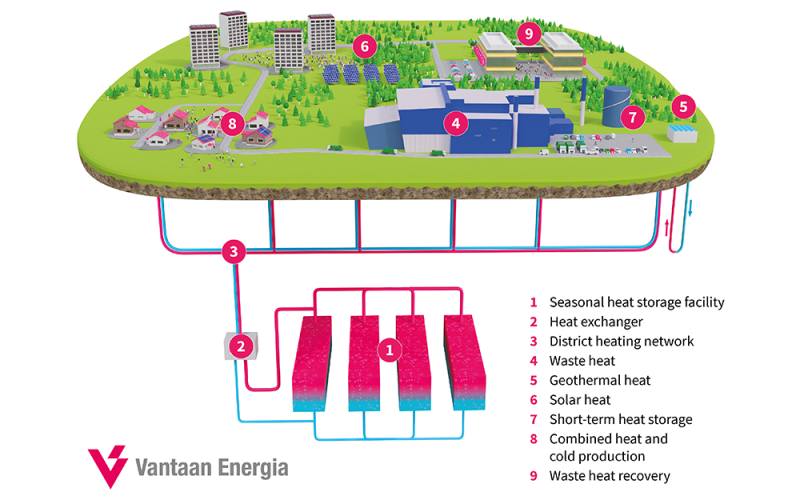

In the next few years, Vantaa Energy intends to build two new waste heat treatment plants as part of its investment program. The plants will energy-efficiently use the most common household and industrial waste classified as hazardous as well as treated wood waste.

The new plants are linked to an investment program to phase out fossil fuels, which will reduce emissions from energy production and is therefore an important part of Vantaa Energy’s climate promise to achieve fossil-free energy production by 2026.

It was decided to implement the projects as a project alliance, and Boost Brothers Ltd, a construction management company, has been selected as the service provider for the establishment of the alliance. In addition to planning and construction, the alliance is responsible for overall project coordination and its main objective is to enable the operational capability of facilities through high-quality project management.

The core of the alliance project is to enable to achieve the operational objectives of the plants

An alliance means an organization in which the cooperation partners are jointly responsible for the planning and implementation and share the risks and benefits. Vantaa Energy wants to implement the construction projects for these new plants with the alliance model.

Vantaa Energy has previously implemented similar projects using the EPCM model. In these projects, it has identified development needs related to the model and has concluded that the best conditions for success in the new plant project are achieved with a project alliance responsible for the implementation of the entire plant and committed to the objectives of the entire plant.

As part of the search for an alliance partner, Boost Brothers and Vantaa Energy organized a market dialog. Based on the feedback from this event, the cooperative form of implementation (alliance) interests also the operators, and service providers want to go more extensively in this direction as well in industrial locations.

This project is, as far as is known, the first overall project alliance implementation in the industrial sector in which the alliance is responsible for managing the whole, including construction, a significant part of equipment procurement, coordination, and control, among other things. The main equipment purchases are made by the client, but their integration into the alliance is one of the most important tasks of the alliance.

Matias Siponen, Business Development Manager at Vantaa Energy, highlights the benefits of the alliance project and explains why the alliance model was chosen for these plant projects: “The objectives of the project alliance are almost identical to the objectives of the whole project, with all parties wanting to achieve and even exceed them. All parties have a strong interest in highlighting and managing risks and opportunities on a low threshold in the interests of the project.”

Towards the agreed goals using the Milestone model

The projects will use the Milestone model developed by Boost Brothers, where the project will be guided by milestones. The client has had bad experiences in the past where, after the approval of the plans, industrial projects at the site stage require significant cost-raising changes that would have been foreseeable with better planning, coordination of the plans and procurement planning. For this reason, the client requires a plan and acquisition package procedure in this project.

“In line with the company’s strategy, production will be made more competitive and environmentally friendly. Thanks to the new plants, we will move mainly to domestic sources of energy, which means that we will be less dependent on imported fossil fuels and thus the amount of CO2 emissions will be reduced in Vantaa.

At the project level, our main objective is to enable the facilities to function, and by using the Milestone model for projects at both planning and implementation stages, we are continuously informed that the project is progressing towards jointly agreed objectives. By anticipating potential issues, we will avoid unpleasant surprises, for example in terms of timetables and costs,” says Siponen.

A new way of implementing industrial projects is sought

Boost Brothers is responsible for establishing the project alliance for the projects. We are in the acquisition phase of the alliance.

“The interest in Vantaa Energy heat treatment plant projects has exceeded all expectations. We have managed to build trust with the service providers and have received good feedback from the bidders on the solutions presented in the project preparation,” explains Matti Sivunen, Chief Operating Officer of Boost Brothers.

“The alliance model is suitable for industrial projects. When the builder is involved at the early phase in creating the project control system, developing plans, and submitting market information, for instance on the timing of procurement and the optimization of content, the best conditions for success of the project are created,” continues Sivunen.

Sivunen explains how to view the current bidding process: “The market survey found out that service providers have a wealth of ideas on how to implement the project. For this reason, the bidding process seeks to be sufficiently transparent with regard to things such as assessment criteria. The procurement documents have been constructed in such a way as to enable different solutions based on the tenderers’ own strengths and proposals. We want to give the tenderers space to create better solutions.”

The project alliance has the ingredients at hand to create a completely new way of implementing industrial projects. It is the responsibility of the alliance to create good foundations in the development phase for high quality management of the project. The alliance is responsible for coordinating the delivery of the main equipment, which is the basis for the success of the whole project. In addition, the pre-prepared change management process supports the project’s smooth progress.

The alliance partner will be selected during the summer of 2021. The objective is to have the plants in operation at the beginning of 2024.